AIR DRYER

AIR DRYER

WORKING PRINCIPLE : Saturated compressed air enters to the Air to Air heat exchanger, where it is pre cooled by outgoing cold dry air. Highly effective pre cooler reduces the temperature considerably, and enables to use smaller & economical refrigeration system. Then the pre cooled, relatively low temperature compressed air enters to Air to refrigerant heat exchanger, where it is cooled down to +3°C (Pressure Dew Point). At this temperature, moisture in vapour from condensed to liquid form, and separated from the compressed air by moisture separator and discharged to drain port through automatic drain valve. The cold dry compressed air passes back to Air to Air Heat exchanger, and gain temperature by exchanging heat with incoming warm air. The dry air coming out from the dyer is ready to use for instrumentation and process air applications.

Applications: : Automobile * Breweries & distilleries * Cement * CNC Machining * CMM Machines * Chemical * Food processing * Foundry * General Instrumentation * Hospital * Packaging * Paper * Painting * Pharmaceutical * Power Plants * Printing * Rice Mill * Sugar * Textiles * Tool room etc…

REFRIGERANT :- R-22, R-404-A, R-134-A

Flow capacities in air suction of FAD 20°C (68°F), 1 bar (14.5 PSI) at the operating conditions mentioned belowRated power is the max power Consumed at 45°C inlet & 45°C ambient temperatures.

Voltage range 180 to 240V for 1Ø & 380-450V for 3Ø

Note :For any other voltage and frequency, please contact factory.

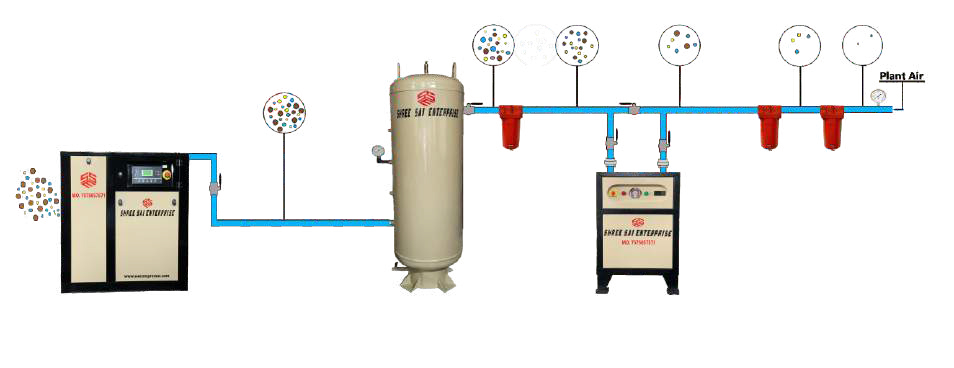

TYPICAL COMPRESSED AIR SUPPLY SYSTEM