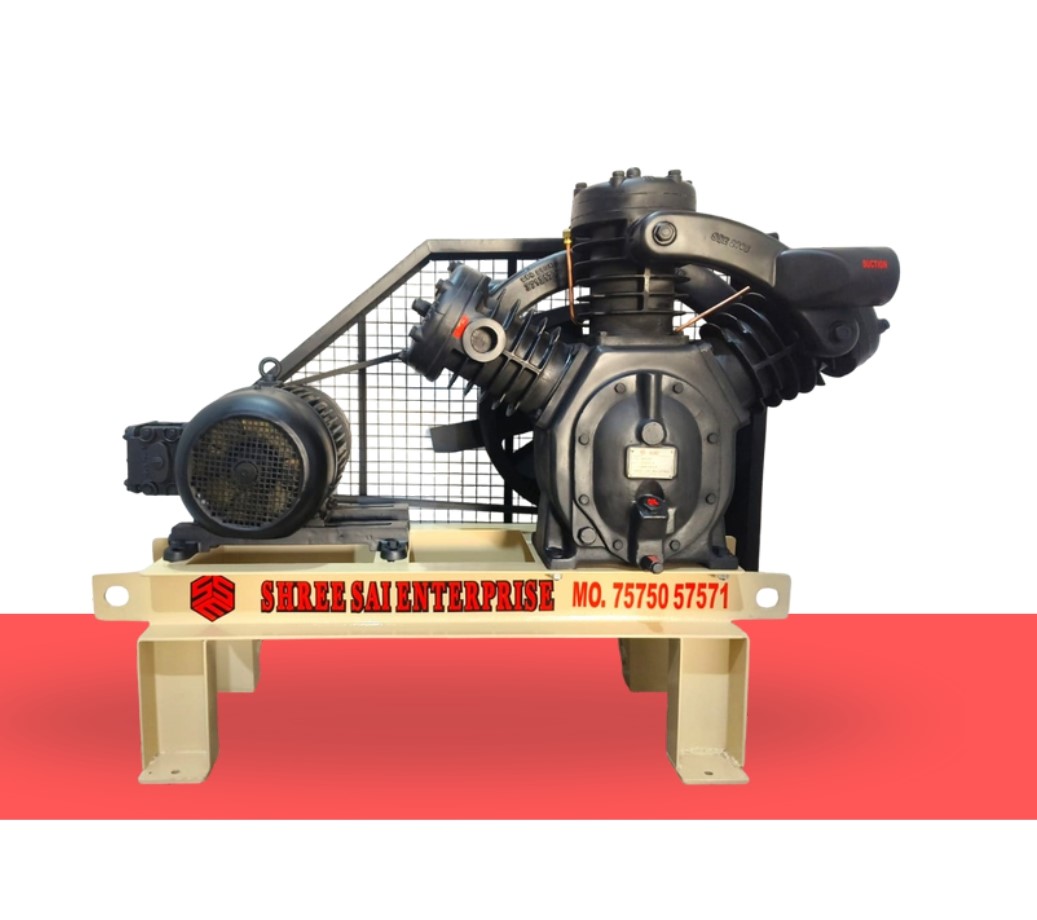

RECIPROCATING DRY VACUUM PUMP & VACUUM BOOSTER

RECIPROCATING DRY VACUUM PUMP

& VACUUM BOOSTER

Vacuum is one of the most versatile of power sources. It can lift, hold, compact, evacuate, move, dehydrate, agitate, actuate, form, rotate, filter, clean and simulate high altitude. In printing, plastic, material handling, food processing, packaging, health care and many other industries, vacuum is called upon to perform many essential functions. Producing a vacuum for modern industrial applications requires a method of air removal that is simple, dependable to operate and maintain.

All of these requirements are met by the SSE air cooled reciprocating single stage and two stage vacuum pumps. These pumps achieve vacuum up to 730 mm (28.74” Hg) for single stage (With vacuum booster 750 mm (29.52'' Hg)) and up to 750 mm (29.52" Hg) for two stage (with vacuum booster 755 to 758 mm (29.72 to 29.84'' Hg)) configuration, at sea level.

STANDARD FEATURES

CAST IRON CONSTRUCTION - Cylinders and frame are designed with 100% cast iron for durability and long life.

CYLINDERS - Separately cast cylinders with deep fins allow for 360° cooling, removing the heat of compression. Individual bolting of the cylinders to the frame for easy inspection and maintenance.

PISTON RING - Each piston is equipped with (2) compression rings and (2) oil control rings to maintain maximum operating eciency and low oil carryover.

VALVES - Stainless steel valves are readily accessible and inexpensively replaced if necessary

CONNECTING RODS - One piece design permits precision aligned machining of both crankpin and piston pin bearing resulting in longer bearing life. Also allows for simple maintenance – no bolts to come loose or adjust.

NOTE

1) These vacuum pumps can be supplied bare or base – plate mounted.

2) Optional items: Scrubber tank, Vacuum gauge and low oil level switch.

3) Performances indicated are at Ankleshwar sea level