ROTARY SCREW AIR COMPRESSOR

ROTARY SCREW AIR COMPRESSOR

High Quality Accessories Show

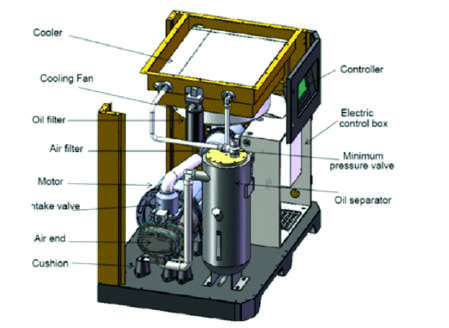

Air End (German / Baosi / Hanbell Technology)

Famous brand air end with SKF bearing, the powerful heart decides the high performance of the whole machine,to make sure bigger air capacity, higher eciency, high precision process rotor, extend the life of the moving parts eciently.

Control Panel

Shree Sai control panel provides the most cost-effective maintenance program, to ensure trouble-free operation, almost like a built-in service technician.

Cooling System

Design of a large heat exchange area, can effectively avoid high temperatures and adapt to bad working conditions to ensure longer life.

Electrical Board (Siemens / Schneidder / Crompton)

Main electrical components use the world-famous brand Schneider, Siemens, etc., professional wire input design, strong function to diagnose fault and protect automatically.

Motor

Using a well-known brand high-performance motor, protection class Ip54, F Class insulation, SKF load bearing, higher eciency than similar products by 3%-5%.

Intake Valve

Automatically adjusts based on gas consumption, low maintenance, good stability, large inlet air.

FEATURES

- 2 Years of warranty for Screw Air End.

- Oil cooler is designed at 45°C ambient Temp. Which is suitable for Indian Industrial circumstances.

- All Parts are designed with universal design code / standard.

- Consumable cost is low up to 35% as compare to others.

- Thermostatically operated fan motor.

VFD WITH PM MOTOR :

A Revolution In Energy Saving VFD (Variable Frequency Drive) With Pm Motor

With the motive to reduce the energy cost in our Air Compressors, we now introduce energy saving permanent Magnet Motors with our VFD models which decrease the energy consumption substantially to save even more energy as well as money.

WHY PM MOTOR ?

- Interior PM (IPM) Motor Eciency upto 94.5%, which Outperforms le3 eciency level.

- On Average 20% lower specific energy requirement than the current VSD models.

- On top of energy saving, Free Air Delivery (FAD) increase up to 12% over the range.

- SSE small in size IPM motor has no bearing which means no wearing parts, no maintenance on motor side and no gear or belts, leading to a transmission eciency of 100%

STANDARD QUALITY VFD

FEATURES

SMOOTH START- UP:

The VSD is soft starting, enabling controlled acceleration and deceleration which reduces stress on mechanical components and enhances systm reliability. This results in increased life of the compressor.

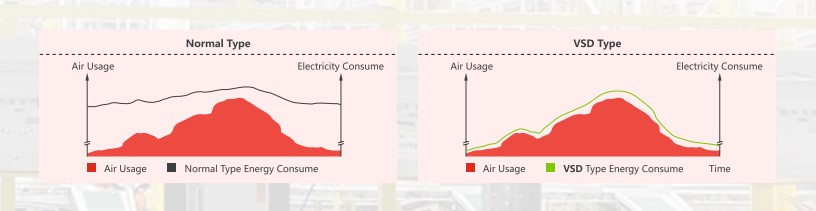

SMART CONTROL:

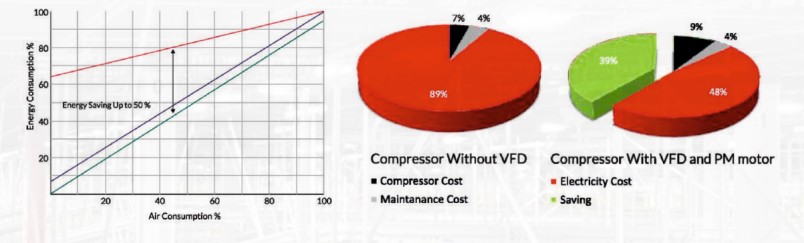

VSD keeps desired line pressure constant, adjusting automatically accordingto system air consumption by varying motor speed. The Compressor onlyconsumes the energy needed to produce the compressed air required by the system. In fixed speed if compressor operates on no load,energy is wasted while no work is performed. VFD with PM motor saves up to 39% energy compared to conventional cycling.

A fixed speed compressor operates on a load – unload band of at least 10 PSI around the working pressure, where’s with VSD compressor can be operated within a band of 2 PSI. For every 2 PSI reduction in operating pressure, there is 1% power saving.

5 YEARS LIFE CYCLE COST WITH VFD & WITHOUT VFD

SAVINGS OF ABOUT 23 LAKH RUPEES IN 5 YEARS

COMPARISON OF ENERGY CONSUMPTION OF 37 KW.

COMPRESSOR AT 50% LOAD FOR ELECTRIC RATE RS. 8/- PER KW.